08/02/2021

LIFE PlasPLUS attends a webinar on Fire properties of polymers and Flame Retardants

PLASTIWIN, the Walloon business cluster for plastic, hosted a webinar “Fire properties of polymers and Flame Retardants (FR)” on 2 February 2021. Plastiwin is a sectorial network devoted to industry, focusing on the development of high added value products and solutions, by the use of methodologies based on value chain, open innovation and networking.

MATERIA NOVA, a Walloon-based EU R&D center focused on the development of innovative materials was the presenter for the webinar. LIFE PlasPLUS was represented by Philippe Giaro, University of Liège.

The webinar titled “Fire properties of polymers” covered many topics notably :

- Fire protection with a focus on Active Protection and fireproofing of materials :

- Fire reaction: Resistance to ignition, heat and smoke and formation of drops;

- Fire resistance : Mechanical resistance, tightness against flames and hot gases and thermal insulation.

- FR families.

- FR laboratory testing and certification.

- Optimal FR characteristics :

- Basic needs : material and cost performance, compliance;

- Desirable Properties and short/long terms interactions with polymers : minimal interference with polymer structure, wide range of applications, colorless, no migration, no leaching, no impact on mechanical properties;

- Stable and safe processing : vapor pressure, volatility, thermal stability, water solubility;

- Desirable safety parameters : no bioavailability, no physiological activity, sustainable.

With its holistic approach to simultaneously close the loop for two traditionally siloed material value chains, plastics and minerals, LIFE PlasPLUS aims to improve the recycling of high-quality secondary thermoplastic and critical raw materials coming from mixed Waste Electrical and Electronic Equipment (WEEE) and End-of-Life Vehicles (ELV). By producing high purity recycled thermoplastics and antimony (Sb), two materials in very high demand, notably for the emerging electric mobility sector, the LIFE PLasPLUS approach will help these fast-growing sectors to limit energy, water and resource consumption, while cutting gas emissions and recovering critical raw materials at the same time.

Heterogeneous plastic waste is mostly still either landfilled or incinerated. As a result, Critical Raw Materials (CRM) such Sb, a commonly used FR synergist, are permanently lost. Similarly, high-value thermoplastics (PE, PP, ABS, PS) originating from the automotive and Electrical and Electronic Equipment sectors (EEE) are currently being lost, or in the best cases, downcycled. LIFE PlasPLUS improves the recycling of high-quality secondary thermoplastics and critical raw materials with three following major project objectives :

Step 1: Production of high purity thermoplastics

Step 2: Automated multi-class sensor-based sorting and separation of Flame Retardant Plastics

Step 3: Recycling of by-product Sb through catalytic conversion and hydrometallurgy

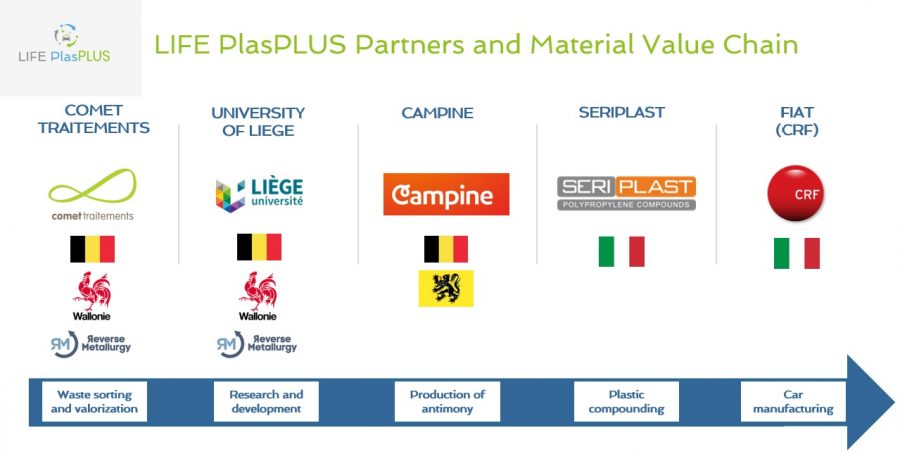

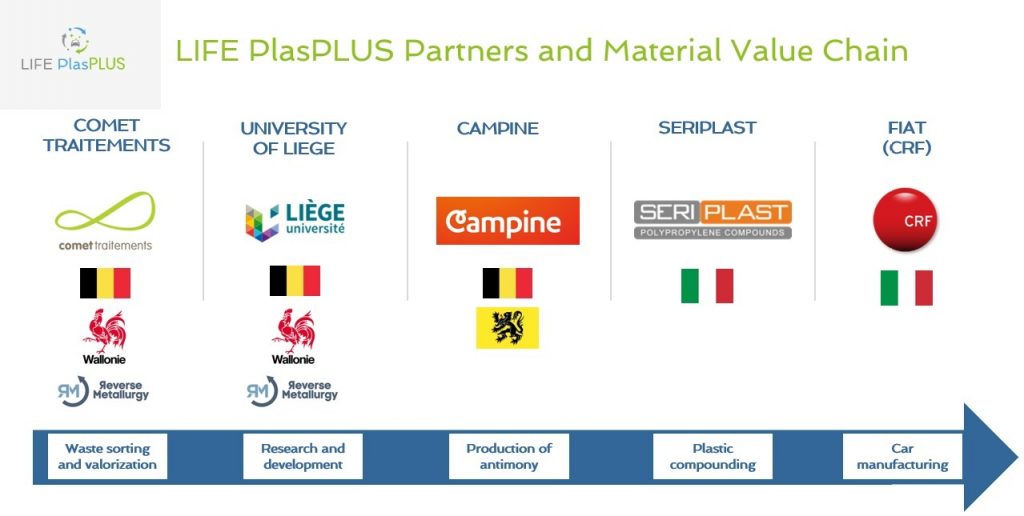

The LIFE PlasPLUS project is being developed under the coordination of Comet Traitements S.A., a Belgian innovative high-growth company processing and recycling shredder residues which are by-products of the shredding of metallic wastes (ELV, WEEE and collected scrap). The project counts four additional Belgian and Italian partners : a university (The University of Liège), FIAT’s research centre (CRF) and two industrial companies operating in active materials and compounding (SERI PLAST and Campine).

LIFE PlasPLUS warmly thanks PLASTIWIN and MATERIA NOVA for the great webinar.

For additional information on the subject please visit: www.plastiwin.be or contact Diego Lancksweert at dlancksweert@plastiwin.be (Tel: +32.475.36.00.72).

For more information on LIFE PlasPLUS check out the rest of our website at: https://www.lifeplasplus.eu/.

Stay tuned for the next LIFE PlasPLUS events!